Your global supplier for materials

Coating Thickness XRF 🢂 Mounting and Packaging

The standard “mount” refers to the material and its form, to which the standard material is attached so the user may handle the standard without touching or damaging the standard material. It represents the standard assembly. All standards provided by the accompanying standards lists are given as individual standard assemblies. In other words, each part number represents a single standard assembly unless otherwise noted. In some cases, individual standard assemblies are combined through the use of a “package” or holder to create a set of multiple standard assemblies.

The method used to mount a standard depends on:

1. Is the standard a foil or hard, plated standard?

2. Will the standard be used with a benchtop, microbeam instrument, or a large beam instrument, either benchtop or floor standing, or a portable XRF instrument.

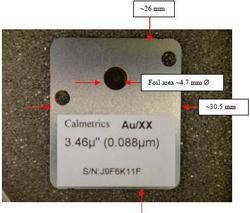

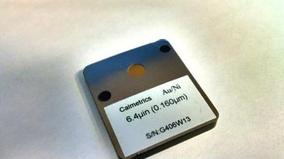

Part numbers that begin with “S” are standard materials mounted to a stainless steel shim with an opening exposing the standard surface, approximately 5 mm in diameter. The steel shim allows the user to handle the standard without actually touching the standard material. All foil standards are normally mounted this way. These standards should be used with any benchtop XRF system with beam sizes less than 3 mm in diameter. The sketch below and example photo show how foil part numbers beginning with “S” appear:

Part numbers that contain “-999” are hard plated standards. These are mounted similar to the “S” configuration shown above. In this case, they should be used with benchtop XRF instruments with beam sizes less than 3 mm in diameter.

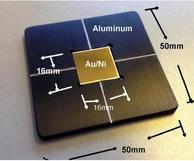

Part numbers which begin with “HH” are plated hard standards or bulk alloy standards. The plated standard is permanently embedded into an anodized aluminum mount which is approximately 50 mm square. The standard may be approximately 16 mm square (typically plated standards) or 19 mm square (typically bulk alloy composition standards).

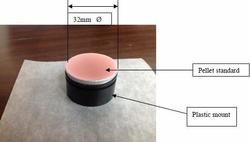

Compressed pellet standards are powdered compounds which are compressed under high pressure to form a 32 mm diameter hard pellet. The pellet is adhered to a cylindrical plastic mount which is also 32 mm in diameter and approximately 19 mm thick.

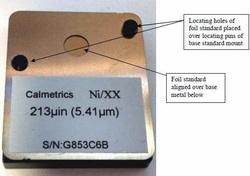

Infinite and Base Standards

Part numbers for most infinite and base standards begin with “S”. The “S” indicates the base or infinite standard will be mounted the same way that a hard plated standard is mounted. However, we do offer an alternative part number series that begins with “PS”. These part numbers correspond with the “S” series. For example SCU999 represents a base Cu standard mounted like a hard plated standard. PSCU999 represents a Cu base standard that is mounted in a special holder with location pins to allow easy alignment of a foil or series of foil standards on top of the base standard. This mounting method for infinite and base standards is not necessary but is helpful when using foil standards that must be placed over a base standard for calibration. This method of base and infinite standard mounting is depicted below: